Piper's Dice for Piper's Dice Tower

Summary

To embark on the mission of learning how to make a custom mold and cast using it, I decided to add to my dice empire by creating the dice to go with my tower. The process of making was entertaining and educational. I learned how to design a mold with proper supports, sprues, and vents. I learned how to edit that design when faced with the realities of pouring molten metal into it, and I learned how to persevere through challenging new tasks.

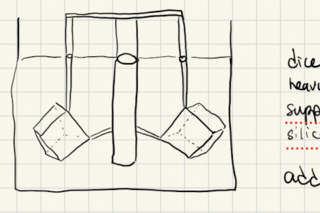

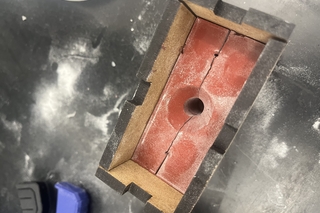

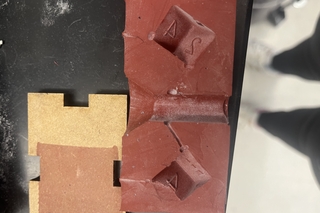

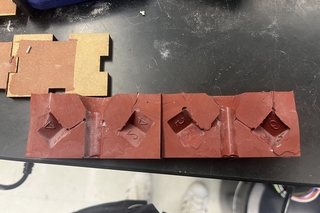

The creation of these dice began with the idea. From there, armed with a lesson on mold design and one trial of making a mold of a coin, I made a preliminary sketch of my design. Initially, similar to the coin we had made, I designed a mold with only one die directly connected to the sprue. I then had the idea, that since most games need two dice, I could attach one to each side of the sprue and make both dice at once. This was the idea I presented in my design review to my classmates and professors. I then learned a lot from their advice. The first concern was separating the dice from the sprue and the definition of that attached corner due to the gate. To address this, I designed smaller runners to go from the sprue to the dice to fill them up with smaller gates. This, however, raised the second issue of stability. The runners would not be able to hold the dice up while the silicon hardened. To address this, I used the vents coming out of the top of the dice and the top of the sprue to build an external support. This way, the vents both served as vents and as support to hold the dice up. This proved successful since the dice did not fall down, and the mold creation worked exactly as intended. Next, I actually had to use the mold. This proved to be more challenging. The trial with the polyurethane went well; I learned that the dice are pretty big, and I needed a lot of material to fill both sides. I made nice half-dice out of the polyurethane. Then, for the pewter, I ran into more difficulties. The first time I tried, the pewter filled the sprue and the runner but made no dice at all. This was partially because the runners were so thin that the pewter cooled before making it into the dice and partially because the pewter covered the vents at the top. I did a couple of things to fix these problems. First, I cut a funnel shape into the top of my sprue with an exacto knife; this helped the covering of the vents problem. Next, I left my mold in the furnace with the molten pewter for a while. This allowed the pewter to successfully travel through the runners without hardening since my mold was quite warm. These tweaks proved successful, and I made four lovely pewter dice. Now, there were still things I was not able to perfect. I had a less-than-ideal surface finish on the dice with a few flaws and cracks. But overall, I’m extremely proud of the work I did on this project, and the dice are so fun to use.