Preparing to Mold

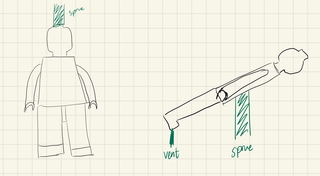

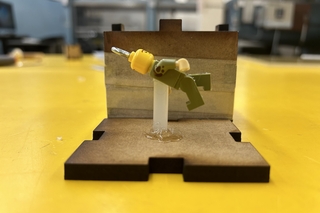

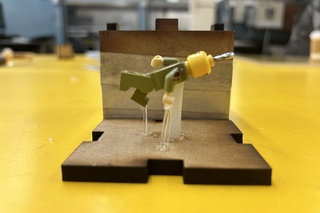

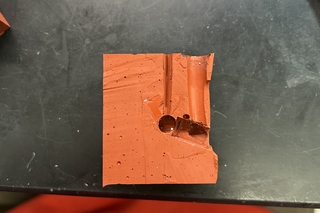

I then began to prepare the lego piece for the mold making process. First, I filled the holes in its legs, arms, feet, and head, using hot glue and a straight edge to flatten the surface. I then modified a small metal eye hook to function as the ring for the key chain and secured it to the head of the lego piece using hot glue. This was to ensure I could cast the entire keychain in one go. Next, I quickly laser cut a 3 x 2 x 2 inch box using the modifiable parameters from the MDF cube we had cut early in the course. I secured the lego piece to the bottom of the box using a glue stick as the sprue, and then went about adding my vent pieces with the filament. I placed a vent at every local minimum on the lego piece which included its feet, hand, chin, and hip. I then assembled the box around the piece and was ready for the liquid mold.